AVANTI

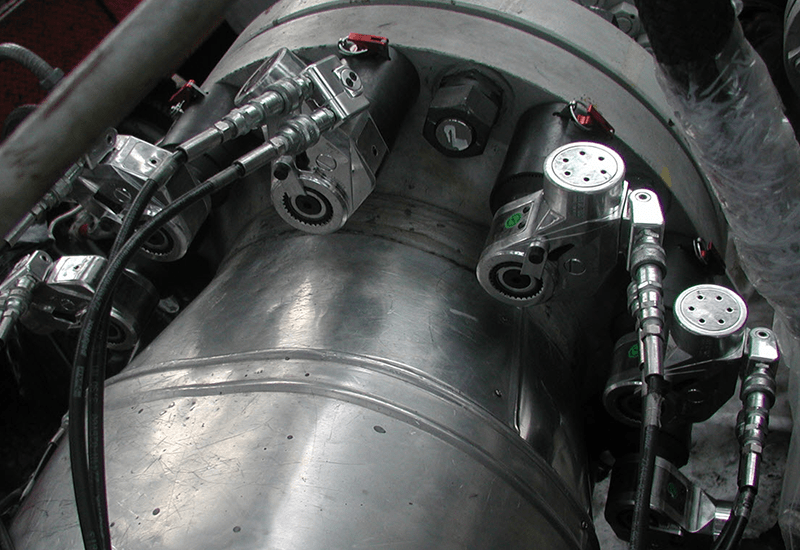

The AVANTI Bolting System offers the widest range of torque output with a maximum output of more than 130,000 ft-lbs in the largest model. With tens of thousands in use around the world, the AVANTI is the industry’s trusted solution for next-generation bolting.

REACTION DRIVE

The Avanti features a patented industry-first reaction drive that eliminates the destructive twisting force that occurs in other torque wrenches that have a back-end reaction arm. (*Also found on ICE series)

TORQUE & ANGLE DIAL

With a simple add-on, the AVANTI system is capable of providing a clear angle reading for bolting methods that incorporate turn of the nut.

MULTI-USE SYSTEM

The Avanti works with all HYTORC bolting systems including tensioning with the HYTORC Nut and the revolutionary new HYTORC Washer for added safety, speed and accuracy on any job

SPECIFICATIONS

Avanti- Metric

| Model | Height (H) | Width (W) | Length (L) | Radius (R) | Drive | Weight | Torque Range |

| AVANTI .7 | 106 mm | 45 mm | 105 mm | 25.1 mm | 3/4 | 1 kg | 153 – 1040 Nm |

| AVANTI 8 | 201 mm | 98 mm | 209 mm | 49.3 mm | 1 1/2 | 9 kg | 1559 – 10521 Nm |

| AVANTI 20 | 260 mm | 129 mm | 278 mm | 66 mm | 2 1/2 | 22 kg | 3742 – 24256 Nm |

| AVANTI 35 | 310 mm | 158 mm | 342 mm | 81 mm | 2 1/2 | 38 kg | 6650 – 43156 Nm |

| AVANTI 50 | 353 mm | 179 mm | 395 mm | 100.3 mm | 2 1/2 | 58 kg | 9765 – 62539 Nm |

| AVANTI 80 | 428 mm | 190 mm | 496 mm | 119.1 mm | 3 1/2 | 127 kg | 16222 – 116187 Nm |

| AVANTI 130 | 493 mm | 216 mm | 577 mm | 134.9 mm | 3 1/2 | 265 kg | 26296 – 187795 Nm |

Avanti- Imperial

| Model | Height (H) | Width (W) | Length (L) | Radius (R) | Drive | Weight | Torque Range |

| AVANTI .7 | 4.19″ | 1.79″ | 4.14″ | 0.99″ | 3/4 | 3.10 lbs. | 113-767 ft-lbs |

| AVANTI 8 | 7.90″ | 3.86″ | 8.24″ | 1.94″ | 1 1/2 | 20.75 lbs. | 1150-7760 ft-lbs |

| AVANTI 20 | 10.22″ | 5.07″ | 10.94″ | 2.60″ | 2 1/2 | 47.70 lbs. | 2,760 – 17,890 ft-lbs |

| AVANTI 35 | 12.22″ | 6.23″ | 13.45″ | 3.19″ | 2 1/2 | 82.75 lbs. | 4,905 – 31,830 ft-lbs |

| AVANTI 50 | 13.90″ | 7.04″ | 15.54″ | 3.95″ | 2 1/2 | 127.70 lbs. | 7,202 – 46,126 ft-lbs |

| AVANTI 80 | 16.84″ | 7.49″ | 19.52″ | 4.69″ | 3 1/2 | 280.50 lbs. | 11,965 – 85,695 ft-lbs |

| AVANTI 130 | 19.40″ | 8.50″ | 22.73″ | 5.31″ | 3 1/2 | 585.00 lbs. | 19,395 – 138,510 ft-lbs |

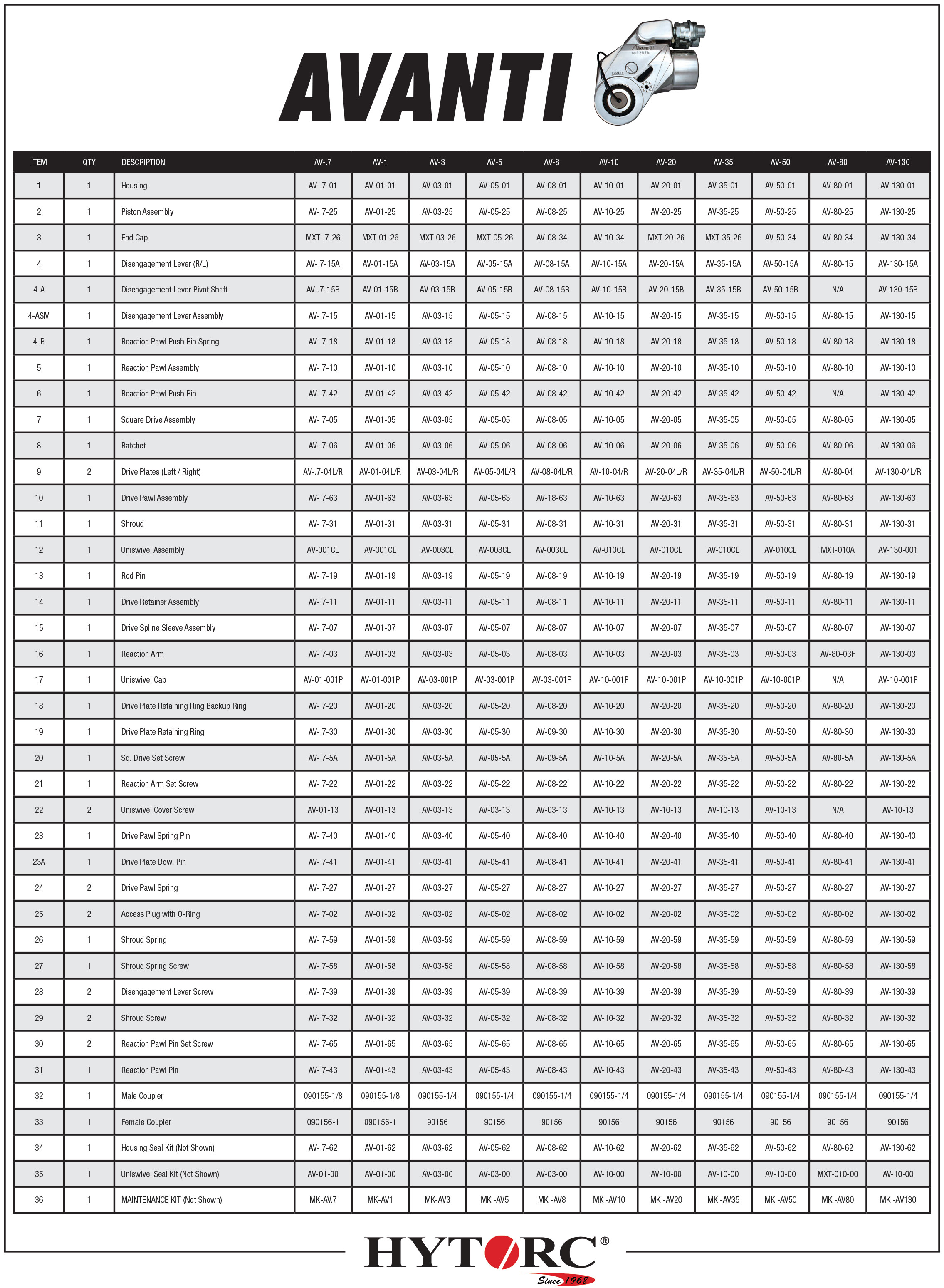

DOCUMENTATION

ACCESSORIES

ECO LINE Sockets

The new coating, Eco Line, has been developed with the aim to protect the environment through an environmentally friendly manufacturing process, but also to help our clients worldwide to respond to new environmental targets.

HYTORC Reaction Fixtures

Custom-Made reaction fixtures guarantee safe and efficient work.

Offset Link

The HYTORC Offset Link provides an extension for HYTORC square drive tools allowing operators to tighten bolts that are difficult or impossible to reach with limited overhead clearance or nearby obstructions.

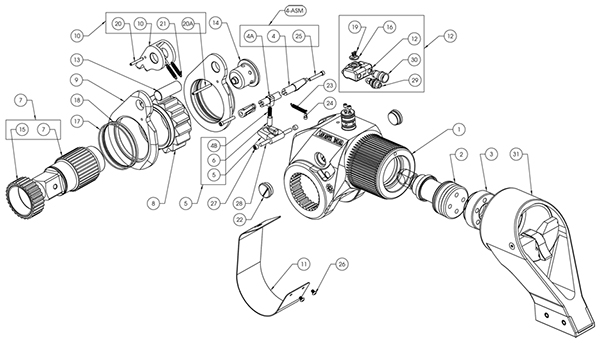

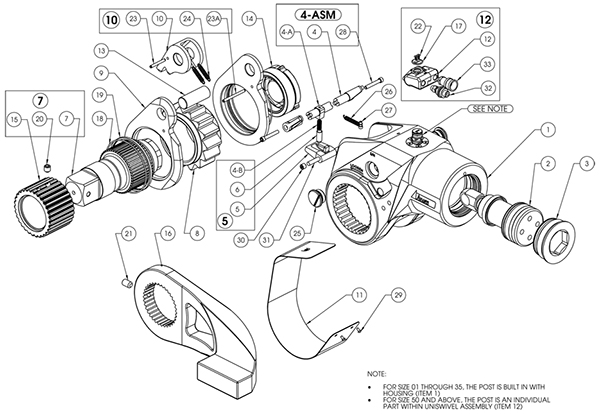

Prior to testing hydraulic torque wrenches. A visual inspection should be done. The visual inspection should include.

- Cracked, bent, or damaged couplers.

- Swivel Assembly

- Cracked swivel block

- Loose swivel assembly

- Swivel post retaining ring is attached

- Loose end cap

- Cracked or damaged housing

Tool does not ADVANCE or RETRACT. Check the following.

- Couplers are loose or damaged.

- Tighten and/or replace couplers.

- Ratchet

- Replace ratchet if the teeth are stripped, missing or damaged.

- Drive pawl Assembly

- Check drive pawl springs for damage.

- Inspect drive pawl for damage.

Tool does not build 10,000 PSI in the ADVANCE position, and there are no external leaks. The tool has an internal leak. Internal leaks are located in two areas, the swivel assembly and the cylinder.

- Swivel Assembly – Tool will not build over 2000 PSI

- Replace damaged swivel seals.

- Inspect swivel post for wear and/or damage.

- Inspect swivel block for damage.

- Cylinder – Tool will not build over 6000 to 7000 PSI

- Check the piston and cylinder O-ring for wear and/or damage.

- Inspect the piston assembly for wear and /or damage.

- Inspect cylinder wall for excessive wear.

Tool has an external leak.

- Swivel Assembly

- Bent or broken couplers.

- Worn and/or damaged seals.

- Cracked or damaged swivel block.

- Damaged swivel post.

- Cylinder

- Worn and/or damaged seals.

- Loose end cap.

- Worn and /or damaged piston assembly.

- Damaged housing assembly.

The tool’s square drive rocks back and forth. Check the following.

- Lever Assembly

- Lever mounting screws are too tight.

- Levers cracked and/or damaged.

- Reaction Pawl Assembly

- Damaged reaction pawl spring.

- Damaged reaction pawl.

- Ratchet

- Replace the ratchet if the teeth are stripped, missing or damaged.